Fiber Splicing

Fiber Splicing

In today’s rapidly evolving networking landscape, seamless data transmission and connectivity are vital. Fiber optic technology has emerged as a leading solution, offering lightning-fast data transfer. However, to maximize the performance of fiber optic networks, it is crucial to have a comprehensive understanding of fiber splicing techniques. By mastering these techniques, you can unlock the full potential of fiber splicing and ensure efficient and reliable network connectivity. Stay ahead in networking technology with expertise in fiber splicing. Discover the power of fiber optics for fast and reliable data transmission.

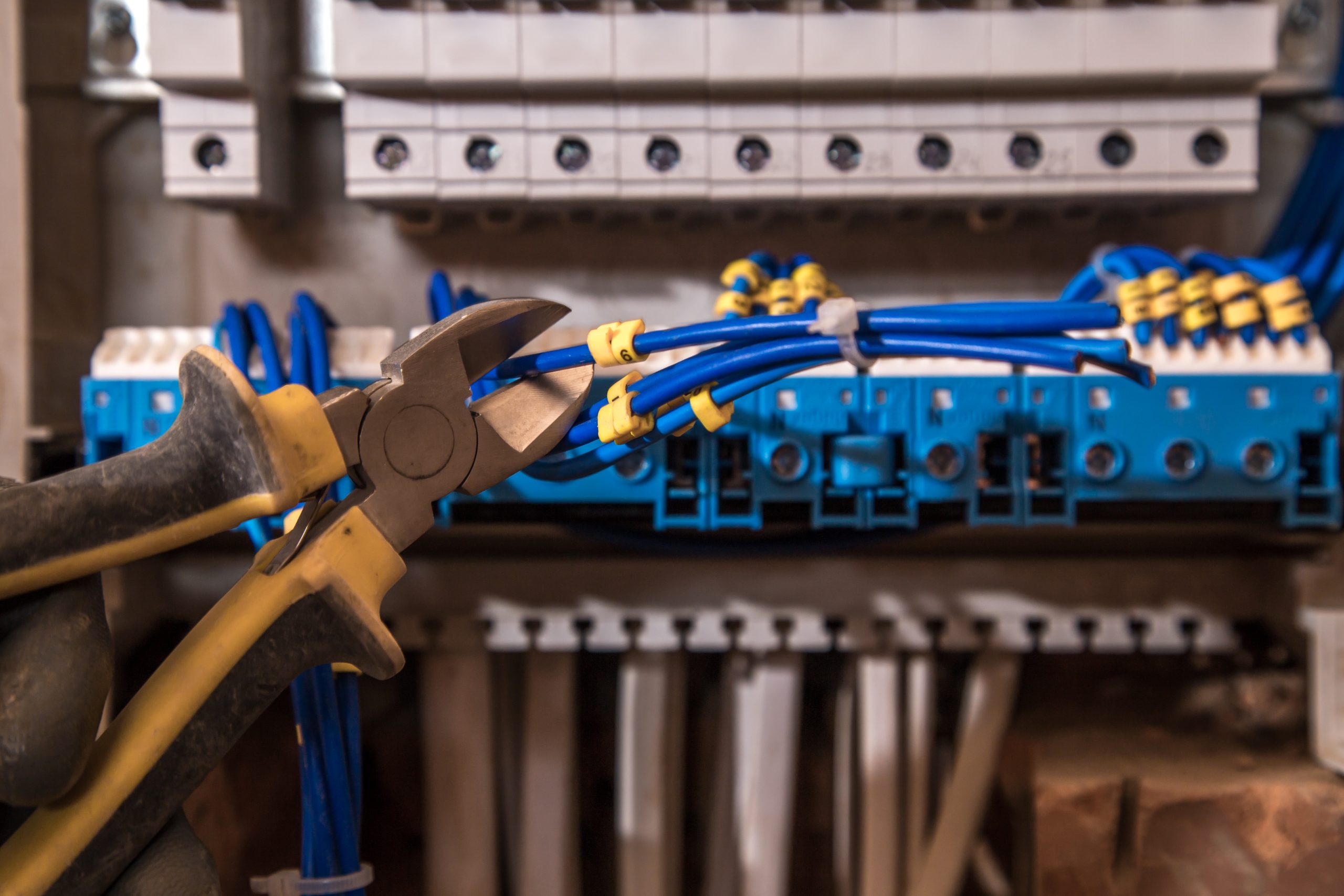

Tools of the Trade

Before delving into fiber splicing, gather the essential tools:

Fiber Cleaver: A cleaver ensures clean and perpendicular cuts on the fiber ends.

Splicing Machine: Fusion splicers or mechanical splicing fixtures are crucial for aligning fibers.

Fiber Strippers: Use these to remove protective coatings without damaging the core.

Alcohol and Cleaning Supplies: Maintain cleanliness to minimize contamination.

Heat Shrink Tubing: Protect the spliced area with heat shrink tubing.

Visual Fault Locator (VFL): A VFL helps locate and identify issues in the

The Fiber Splicing Process

Prepare the Fibers: Strip the protective coating and clean the fiber ends thoroughly.

Cleave the Fiber: Use a cleaver to obtain flat and perpendicular fiber ends. Precision is key.

Align the Fibers: In fusion splicing, the splicing machine aligns the fibers automatically. In mechanical splicing, use the fixture to ensure precise alignment.

Splice the Fibers: Fusion splicers use an electrical arc to melt and fuse the fibers. For mechanical splicing, apply adhesive to secure them together.

Protect the Splice: Apply heat shrink tubing to protect the splice point from environmental factors.

Inspect and Test: Use a VFL and an optical time-domain reflectometer (OTDR) to inspect the splice’s quality and functionality.

Best Practices When It Comes To Fiber Splicing

Maintain Cleanliness: Contaminants can degrade the signal, so always work in a clean environment.

Fusion Splicing for Long-Haul: Opt for fusion splicing when you need minimal signal loss over long distances.

Documentation: Keep detailed records of each splice for troubleshooting and maintenance.

Regular Inspections: Periodically inspect and test splices to detect potential issues early.

Mastering the Art of Fiber Splicing

To ensure reliable and efficient data transmission, network professionals must master the art of fiber splicing. You can uphold high-performance fiber optic networks by comprehending the different splicing types, acquiring the necessary tools, and embracing best practices. Whether you choose fusion or mechanical splicing, implementing proper techniques will ensure a smoothly running network, making fiber splicing an indispensable skill in networking. Use the opportunity to optimize your network’s performance with expert fiber splicing techniques.